QSTONE

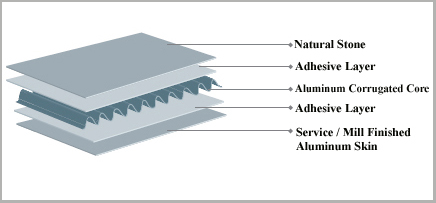

Yet another innovative product of Qnap®. Qstone® is an excellent cladding solution for building fascia with natural stone. Perfect blend of thin Natural stone with backing of our non-combustible ACM (Sinco®) derived as a provides a superior construction solution. Qstone® is another distinguished product from our technological partners (NIT Germany Gmbh) materialized at our production facilities in Qatar for catering the needs of booming regional construction industry.

It is our high-end engineering skills combined with effective imagination evolved as a genuine solution to overcome various practical difficulties in stone cladding of buildings. State-of-the art stone clad qstone® is available in various finishes and sizes, which is doubtlessly an ultimate choice for the cladding industry from our esteemed product-line.

Qstone® is available in various finishes of natural stone of various celebrated sources across the world. It is manufactured at our manufacturing facility in Qatar utilizing expertize of our partners in Germany. Qstone® is natural stone faced cladding made of thin natural stone bonded together with aluminum panels using specially formulated adhesive compound for superior adhesion and longevity. Qstone® is light weight and easy to handle product which makes it superior among other natural cladding solutions for interior and exterior

Advantage of Qstone®

Light weight

Qstone® is a lightweight natural stone solution while natural stone are generally weighed at an average of 68 Kg per Square Meter Qstone® is approximately one third only which makes it convenient to use in high-rise buildings.

Fast, Easy & cost effective

Qstone® panels are Thin and light weight panels are easy to handle and fix it over light frame work which ultimately reduce construction time as well as load of the building.

Aesthetic Natural Finish

Stones always fascinated man with its natural beauty throughout history. At times of vertical developments high-rise building has load limitations to use which restricts natural stone claddings on it, qstone® provides an excellent solution of natural finish for such buildings.

It is an ideal cost effective solution for magnificent and aesthetic interiors of lobbies of hotels and commercial buildings

SINCO

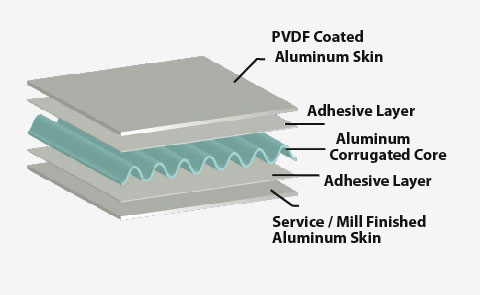

Aluminum Composite Panels with Non-Combustible Corrugated Metal Core and Color Coated Aluminum Sheets on either sides manufactured using Hi-tech Lamination technology. SINCO is available in various Colors, Finishes, and Sizes.

Non-Combustible corrugated Aluminum Core provide enhanced Fire Resistance and Light weightiness for the SINCO. SINCO is classifed as Class A2 as per DIN 4102-1 and certified as Low emitting products and materials for General Construction materials/ Wall cladding by Greenguard Environmental Institute.… Read More

Advantage of Sinco over other Metal Composite Panels

Non-Combustible Core

Non-Combustible Core

Resistance to Heat

Resistance to Heat

Light Weight

Light Weight

Eco Friendly (Fully recyclable)

Eco Friendly (Fully recyclable)

Durability

Durability

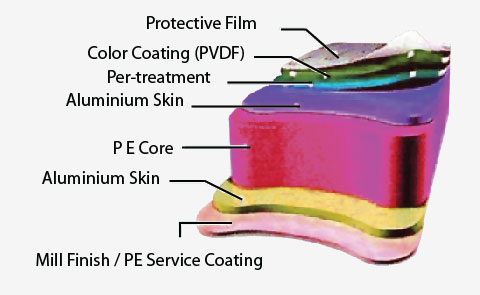

ACP PE

Aluminum composite panel is consists of two sheets of aluminum, sandwiching with a solid core of extruded thermoplastic (LDPE).Core material formed in a continuous co-extrusion process with no glues or adhesives between dissimilar materials. This type of panels are used in less fire risk areas.

Exterior of panel is Aluminum Sheet Coated with PVDF/Lumiflon and rear side is available as Mill Finish / Polyester Service Coat / Chromate. The panels are available in standard as well as customized sizes, colors and finishes.

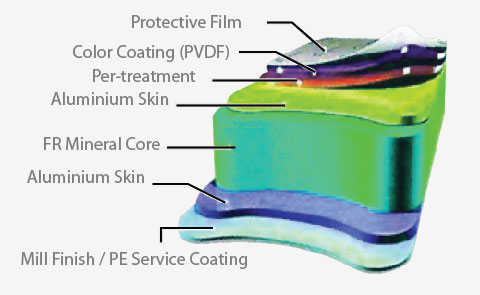

ACP FR

Aluminum Composite Panels with Fire-Retardant Mineral Core and Color Coated Aluminum on either sides; manufactured through continuous co-extrusion process. ACP (FR) is available in various Colors, Finishes, and Sizes.

QNAP Fire-Retardant ACP composed of aluminum skins and the re-retardant core (non-combustible Mineral Filled core). It passes / exceeds all international Fire-safety codes & standards for exterior and interior applications. In Comparison with solid aluminum panels ACP (FR) is lightweight, rigid , at and Cost e¬ective. Exterior of ACP is coated with fluorocarbon paint (PVDF/Lumifon) and the rear side is with a Service Coating / Mill Finish.